1, the company profile

For more than 80 years, the company has been a leading supplier of advanced connector products and has been providing high-tech connectivity products to the world's leading electronics companies. From the first generation of the "Tape Recorder Header" in 1932 to today's widely used connector products, antennas, and sensors, the company is committed to providing world-leading innovative products to customers in industrial applications in a wide range of industries, as well as to customers in a wide variety of end markets. By working closely with these customers, the company has become a strategic partner for connected products companies leading the electronic revolution. The group designs, manufactures and sells electrical, electronic and optical connectors, coaxial and flat ribbon cables, connector systems, etc. The company's primary end markets for products are the communications and information processing markets, including cable television, mobile phones and data communications and information processing systems, aerospace and military electronic equipment, and automotive, rail and other transportation and industrial applications. The group has branches in more than 30 countries, more than 170 factories and offices and employs more than 70,000 people worldwide. Our long-standing success story reflects the agile and entrepreneurial culture of our management team, and our unwavering commitment to creating value for our customers. The conglomerate entered China in 1984 and currently has more than 30 factories in China, mainly in Guangzhou, Shenzhen, Zhuhai, Xiamen, Hangzhou, Shanghai, Changzhou, Chengdu, Xi'an and Tianjin. The division of labor and cooperation between the various business divisions shoulder different production goals.

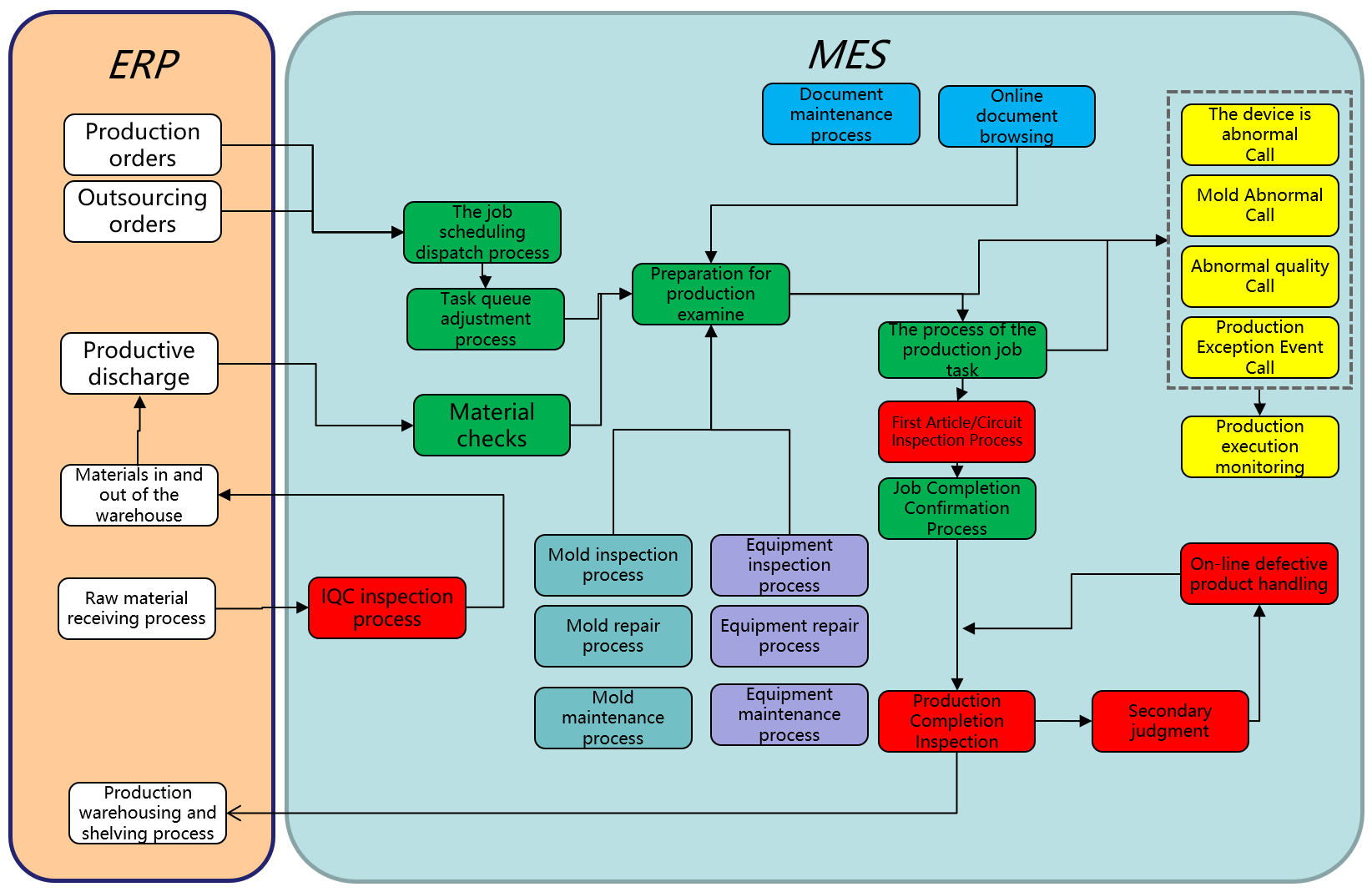

Facing global customers, adhering to the business philosophy of innovation, integration, pragmatism and dedication, we give full play to our precision mold design and development capabilities and the advantages of advanced mold manufacturing facilities, realize the perfect combination of precision stamping and injection molded parts through automation, and work together with customers for win-win cooperation. The terminal markets of the company's products are mainly in the fields of communication electronics, automotive electronics and consumer electronics. Over the years, the company has been focusing on the planning of enterprise resources, and has continuously increased investment in software and hardware. In terms of software, multiple sets of design/management software (such as PRO-E, EMan, ERP, MES) are applied, and in terms of hardware, international advanced equipment is introduced (such as Charmilles machining center, BRUDERER, ISIS punching machine, Nissei injection molding machine), and the perfect combination of software and hardware provides strong backing to meet customer needs.

2、The main functions of the project

Realize the information management of the whole process from the receipt of the production plan to the completion of the product, including the informatization of the business process such as the execution of the production plan, product production, handover, inspection, etc., realize the data collection and display of the business process, record the real-time status of the production process, material error-proofing, product traceability and key production resources, and realize traceable production and transparent production. Build a solid foundation for intelligent manufacturing.

3、Glimpse of the scene

4、Benefit analysis

上一篇:鹰峰电子MES项目案例

下一篇:没有了